Nitrous System Theory, Selection, and Tuning

As modern engines become more difficult to modify, the use of nitrous oxide to obtain phenomenal performance gains is on the rise, and for good reason. We firmly believe that our nitrous systems and related products are the highest quality, performance, and value available anywhere in the world. We can make this claim because we've been manufacturing nitrous systems and components since 1978. The value of this to you is the vast experience we have accumulated throughout the history of our company.

Among the many true bolt-on performance enhancing products available, there are few that can even come close to comparing to the dramatic results of a power increase provided by one of our nitrous systems. In both the simplicity and reliability that you get when you install a nitrous system that carries our world-famous NOS logo, you'll be amazed at how easy it is to produce the one thing everyone is always searching for more of...POWER!

When you consider all of the options you have to get an engine to release all of the potential power it can, there is no equal to the ability nitrous oxide provides you. If you look at a nitrous oxide system on a dollar-per-horsepower basis, you'll find that a nitrous system from NOS can provide the greatest value for each dollar of your precious investments. Our experience throughout the years has proven to us that performance enthusiasts and racers alike are most impressed by the ability to add 10 to 200 horsepower within a period of just a few hours. By carefully choosing the correct system for your applications, you'll be assured of a performance increase and reliability factor that could only be compared to doubling the size of your engine by simply activating your NOS nitrous system!

How to Make Horsepower

An engine operates by burning fuel, which then expands and pushes the pistons down. Want to make more horsepower? Burn more fuel so it will push the pistons down with more force. Sounds pretty simple. But, it's not quite so easy. While there are any number of factors that make increasing power a complex engineering problem, we will deal with three of the most basic ones here.

First, all fuels require oxygen in order to burn. If you want to burn more fuel, you need to also put in more oxygen. Virtually all engine performance products increase power by increasing the flow of fuel and oxygen. Camshafts, larger carburetors or valves, porting, intake manifolds, exhaust headers, superchargers, turbochargers, and nitrous oxide are clear examples of how improved engine breathing (putting in more oxygen in order to burn more fuel) will give you an increase in horsepower. Nitrous oxide injection systems are probably the most efficient way to increase the flow of oxygen and fuel. That's the basic reason why nitrous systems produce such large horsepower increases.

Another basic power factor is vaporization of the fuel. Gasoline, as with other racing fuels, will not burn in a liquid state. The gasoline must be turned into a vapor for it to burn. This process of turning gasoline into a vapor is simple evaporation. It is basically no different from setting a glass of water outside and waiting for it to dry up. In the engine, of course, evaporation happens very quickly. Engine heat and fuel atomization are the keys to accelerating the evaporation process enough to turn raw gasoline into a vapor at 8000 RPM. The process of atomization turns raw fuel flow into tiny droplets which then evaporate faster due to the larger amount of surface area presented for evaporation. The size of the fuel droplets is very important. Take a large droplet of gasoline, break it up into 10 smaller droplets, and you've increased the surface area for more efficient evaporation. The result is more fuel available to be burned and do work during combustion. A well-designed nitrous system will produce very small droplet sizes in the supplemental fuel that flows into the engine with nitrous. This is one of the reasons that NOS nitrous systems can make more horsepower than some other systems.

The third basic power factor we will look at is air/fuel mixture density. Ever try to jog on top of a 10,000 foot pass in the Rockies? Leaves you gasping for breath, doesn't it? That's because the air is thinner, less dense, higher up in the atmosphere than it is at sea level. It is also why you would run slower on a track in Denver than you would near sea level in New Jersey. Density is affected by atmospheric pressure (the weight of the atmosphere above you), heat, and humidity. We can't change the pressure of the atmosphere; but we can regulate the heat of our intake charge to some extent. Cool cams and intercoolers make extra power by cooling the fuel and air/fuel mixture to make it denser. And, the denser the mixture is, the more the cylinder is packed with fuel and air to burn and make power. When nitrous oxide is injected, it turns from a liquid to a gas instantly and becomes very cold. This cold nitrous vapor drops the temperature of the whole intake charge in the manifold by as much as 65 degrees F. The denser mixture that results helps an engine produce even more extra horsepower with a nitrous system.

What Nitrous Oxide Is and What Nitrous Oxide Isn't

To your engine, nitrous oxide is a more convenient form of normal air. Since we are only interested in the oxygen the air contains, nitrous oxide provides a simple tool for manipulating how much oxygen will be present when you add additional fuel in an attempt to release more power. The power always comes from the fuel source. Nitrous oxide is not a fuel. Nitrous oxide is a convenient way to add the additional oxygen required to burn more fuel. If you add only nitrous oxide and do not add additional fuel, you would just speed up the rate at which your engine is burning the fuel that it normally uses.

This, more often than not, leads to destructive detonation. The energy comes from the fuel, not the nitrous.

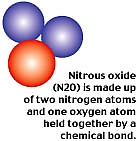

There is no voodoo involved in nitrous oxide. In effect, using nitrous is no different from using a bigger carburetor, a better manifold, a supercharger, or a turbocharger. Understand that the air you and your engine breathe is made up, at sea level, of 78% nitrogen, 21% oxygen, and just 1% other gases. Nitrous oxide (N2O) is made by simply taking the 2 major components of earth's atmosphere (in this case 2 molecules of nitrogen and 1 molecule of oxygen) and attaching them together with a chemical bond. When the nitrous oxide goes into your engine the heat of combustion breaks the chemical bond to provide your engine more oxygen with which to burn fuel. As you've read, all race engines operate under the same principles: more air (better breathing, supercharging, turbocharging, or nitrous) plus more fuel in a denser vapor equals more power.

Nitrous Oxide vs. Other Performance Products

Dollar for dollar, nitrous oxide offers the most performance a consumer can buy. You could spend thousands of dollars on carburet ion, a manifold, valve train components, exhaust, pistons, porting, supercharging, or turbocharging to get the same amount of extra horsepower that a nitrous system would provide for just a few hundred dollars. But this doesn't mean you won't benefit if you also install other performance parts. Once you have installed a nitrous system, all those other performance parts just increase the nitrous power. If you just have a few dollars and want lots of extra power, the best choice is a nitrous system.

Only nitrous is a part time power increaser. All of the standard performance parts put additional stress on the engine and burn more fuel all the time; not to mention what a pain it is to ride around town with a lumpy idle from a camshaft that is barely streetable. Power on demand is one of the great things about a nitrous system; it only works when the driver wants it. All the rest of the time, the engine operates normally; no extra stress, no extra fuel use, and no driveline problems.

What You Get When You Buy a Nitrous Oxide System from NOS

Of all the components in your NOS system that you see when you take it out of the box, there are three things that you may not fully recognize until you have gone through the installation process and used your NOS system for the first time.

- Integrity. We stand behind our products. If we claim a system is capable of 100 horsepower, it's because we designed it that way, tested it that way, and manufactured it that way. If you are willing to follow our guidelines, you'll get the results that we say you'll get.

- Quality. There are a lot of things we do everyday here at NOS. We test our products and systems on sophisticated measuring equipment as well as the real-world environment of the vehicle it's intended for. We pay strict attention to the manufacturing procedures required to maintain our high standards for components. We listen to what you have to say about the performance of our products along with your suggestions for new applications. Our Tech staff relays your comments to our research and development staff to constantly re-evaluate all products to ensure they are up to date and effective for the intended application.

- Experience. We have been manufacturing nitrous oxide systems for over twenty years. We have learned from our successes as well as our failures. We take this knowledge and apply it in very heavy doses to the products we design and manufacture. Even though today may be the very first day that you have installed and used one of our systems, you've got twenty years of nitrous experience with you every step of the way. It's there in the box. You may not see it; but you'll definitely feel it.

Nitrous Oxide and Emissions

Use of nitrous oxide (N2O) doesn't necessarily increase the oxides of nitrogen (NOx) that pollute the air. Of course, NOS makes "race only" systems that are not legal for use on pollution controlled engines. However, many NOS systems have received certification for 50-state emissions legal use in the United States. The approvals for use on emissions controlled vehicles were obtained by independent laboratory testing which proved that these NOS systems do not increase tailpipe emissions in normal driving conditions. We recommend only emissions legal nitrous kits for use on engines subject to emissions and regulations.

Types of Nitrous Oxide Systems

The two most popular types of nitrous oxide systems are spray bar plate systems, such as the Powershot, Cheater, and Big Shot automotive systems (which use a spacer plate between the carburetor and manifold) and direct port. The plate adds nitrous and supplemental fuel to the intake air stream through built-in spray bars. Plate systems are used on automotive engines on the street and in many racing classes.

Direct port systems use specially designed injectors, FoggerTM nozzles, to add the nitrous and supplemental fuel to each individual intake runner. These systems can flow huge amounts of nitrous and fuel while distributing it evenly to every cylinder. Multiple stage direct port systems have produced much more than 500 extra horsepower on some pro racing engines. All NOS Direct Port systems feature changeable nitrous and fuel jets for horsepower adjustments and system tuning. Direct port systems are used in both street and racing applications on virtually every kind of engine. Some nitrous systems for fuel injection are a variation of Direct Port technology.

Tuning Your NOS System:

A Few Important Points to Remember:

- Although this may seem like a very basic factor, failure to thoroughly read the instructions is the number one reason your system installations will not be successful. Read ALL the instructions included with your system BEFORE you do anything at all! You may find that you need to change something on your engine or find that we've designed something new that is different from some of the systems you may have seen in a magazine article. Save time and headaches by taking the time to thoroughly read all of the instructional materials. Call the NOS tech dept. if you have any questions.

- Always start conservative. Follow our recommended jet combinations and start with the lowest level if you have an adjustable system. It only takes a few moments to change the jets so don't take unnecessary risks by starting at the highest level.

- Be realistic about how much power your engine will handle. Don't get carried away here. Only you know exactly which components are in your engine. If you are unsure about those components, you can call our tech line and one of our highly experienced tech personnel can help you to decide what is safe for your particular combination. If you don't know what's inside your engine, then you are most safe by assuming that the components are factory stock and choose the correct system for that application.

- The power comes from fuel. The additional power is set by the amount of additional fuel your system supplies while the nitrous system is in operation. If the fuel isn't there, the power won't be either and no amount of nitrous or anything else can bring it back.

- There are two controls typically available to manipulate the amount of fuel available during system use; the fuel jet size and the fuel pressure. The correct fuel pressure is read while the system is flowing fuel. Some fuel pressure regulators give false readings because the pressure reading will creep up when the system is not activated. When this happens, the actual flowing fuel pressure will be much lower than expected and can cause problems.

- When problems with misfire or detonation are encountered, ALWAYS reduce the size of the nitrous jet first! Remember that the power comes from the fuel, not the nitrous, so trying to cool things down by adding fuel simply adds more power and complicates the problem. Carburetors jetted over-rich run cooler and release less power. Nitrous systems jetted over-rich will possibly just release more power, so if you run into problems, reduce the size of the nitrous jet(s) first.

- When you check your spark plugs for signs of how your system is operating, CHECK EVERY SPARK PLUG, not just the easiest plug to get to. No two cylinders ever run exactly alike. Nitrous has the unique characteristic of cleaning the spark plugs very well and leave them looking like you just installed them. If there are any signs of detonation such as tiny silver or black specks deposited on the porcelain, reduce the nitrous jet size. If the ground strap of the spark plug exhibits a bluish-rainbow coloring, reduce the nitrous jet size. If the ground straps shows signs of melting, reduce the nitrous jet size and change to a spark plug with a shorter and thicker ground strap.

- If your system suddenly begins to experience problems even though you haven't changed anything, the culprit is most often a clogged nitrous or fuel filter. The instructions that come with your system contain information about where the nitrous and fuel filter screens are located. Check them periodically.

- If your experience any problems you don't understand or can't cure, don't hesitate to call our tech line. We're here to help you get the most from your NOS System.

Spark Plugs and Nitrous Oxide:

What Works, What Doesn't, and Why Over the years there seems to have been a great amount of technical material written about the simple operation of a spark plug and what they can do in relation to the way an engine runs. There are a few basic characteristics about spark plugs that you need to know to make an intelligent choice about the correct spark plug for your application.

First, and most important; a spark plug must be of the correct design to operate within the environment of your engine, not the other way around. This means that the spark plug has virtually no influence on how the engine burns fuel or runs in general. The correct spark plug will simply survive the conditions present in your engine. A spark plug must maintain a certain temperature to keep itself clean. The wrong heat range can cause an overheated plug or a fouled plug. The heat range refers to the temperature of the ceramic material surrounding the center electrode.

Lean air/fuel ratios are more difficult to light because there are less fuel molecules in the area of the plug gap when the plug is scheduled to fire; thus, projected nose plugs were designed for late-model lean-burn engines. Modern high-energy ignition also allowed larger plug gaps. All the while this was happening, something else happened. Something that no one seems to have really noticed as the real culprit when the issue of factory type plugs being used with nitrous comes up. We'd like to clue you in.

Quite often, a factory type, wide-gap projected plug will produce a misfire condition after only a few seconds of nitrous use. The misfire is not due to the heat range. The misfire occurs because the ground strap of the spark plug becomes a glowing ember because it is too long to dissipate the extra heat produced by a nitrous-accelerated burn condition. The correct fix for this phenomenon is to replace the plugs with one that has a shorter ground strap. By doing this, you will shorten the path for the heat being absorbed by the ground strap. You can use the same heat range, you just have to find a non-projected nose plus with a shorter and preferably thicker ground strap.

If you only change the heat range of the spark plug to a colder heat range, you may very well still have the misfire problem. Since the length of the ground strap is the cause of the misfire, a colder spark plug may have the same length of ground strap as the hotter plug you replaced it with.

Spark plug gaps should generally be .030" to .035". Never try to gap a plug designed for an .060" gap down to .035". Find the correct non-projected nose plug designed for an .035" gap.